- About us

- Spheres of application

- Equipment

- Injection molding machines

- Spares

- Lines

- Service

- Contacts

The complete automation of each transport plant is obtained by stocking the materials in containers that allow the collection continuously.

For indoor storage areas or protected areas we can use modular silos that offer the great advantage not to occupy to much space during the transport.

Being completely modular have so a practical and economic loading system.

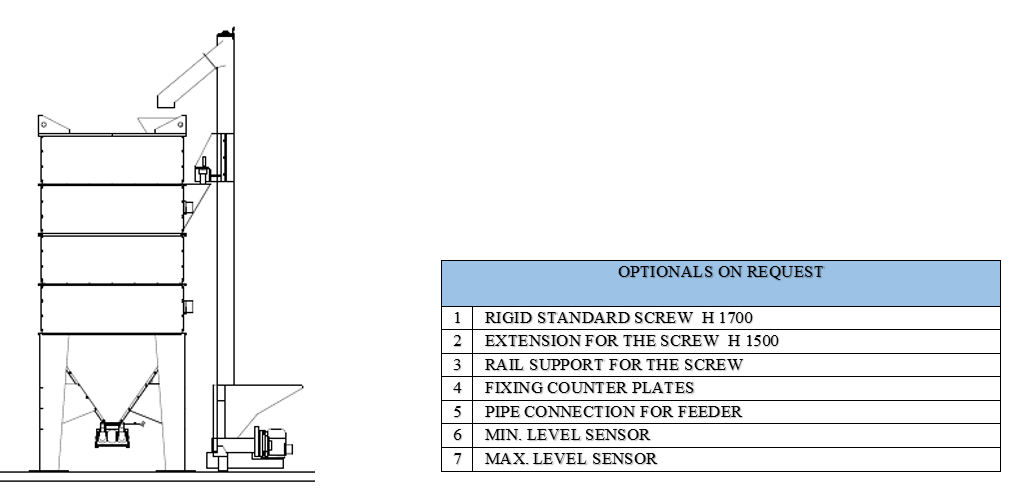

Made of modular modules of robust galvanized carbon steel, resting on the ground on 4 stable supports, it is certainly the best that the market can offer for the storage of medium quantities of granules in closed environments or under roofs. The construction principle is the same for all SILMO models: there is a base of 1.500 mm height, on this base are added the stackable models of 554 mm height. Also the thickness is the same for all models: 2 mm. The particularity of SILMO is the extreme ease of assembly, and the versatility in use. It is essential as a sucking point for the centralized feeding system, for the storage of materials contained in Octa-bin or in Bag Bag or for the storage of materials coming from granulators or recycling plants.

The feeding of the granule can be done with one screw conveyor or through granules launchers or with vacuum feeders. The sucking from the SILMO can be done with fluidification valve for the centralized feeding system that is placed on the bottom of the cone or on the side of the cone with a butterfly valve for the manual collection in containers. The SILMO is provided with closing on the top to avoid the contamination of the material or for the powder’s leak.

The dimensions of the conical section are: 1.500 mm each side, 1.457 mm height, capacity 703 lt; the additional modules have a height of 529 mm and a capacity of 1.090 lt. On request the SILMO are available also in AISI 304.